© Copyright 2024

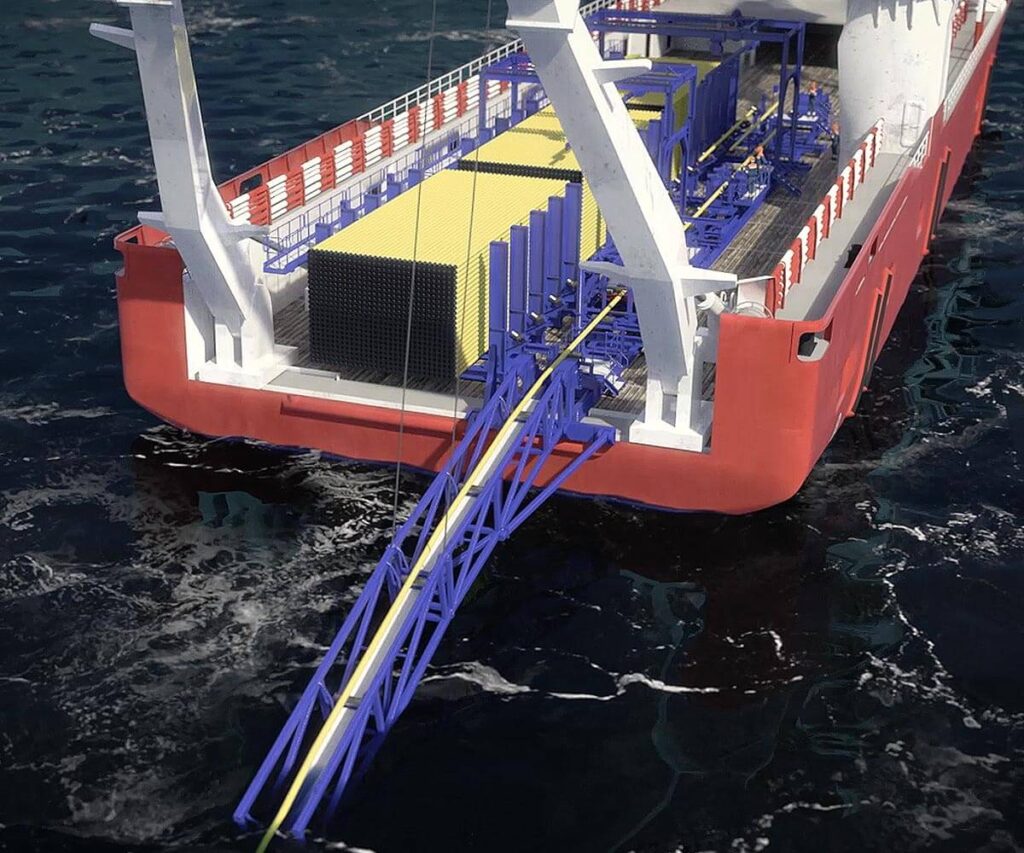

NuForce Pipelay Services – Modular Pipelay System (MPS®)

_

Cortez Subsea leads the charge to offer the most cost-effective rigid, flexible and coiled pipelay methods in the world. We use our own designed and patented MPS® to offer a weld-free, semi-autonomous pipelay process which is coupled with mechanical connectors to offer an efficient and economical alternative to welding which is quicker, stronger, safer and cleaner. The MPS® is pre-assembled and uses smart-deck fastening to allow for ease of transportation and minimal mobilisation time. Dictate your own schedule with this flexible solution.