Who we are

_

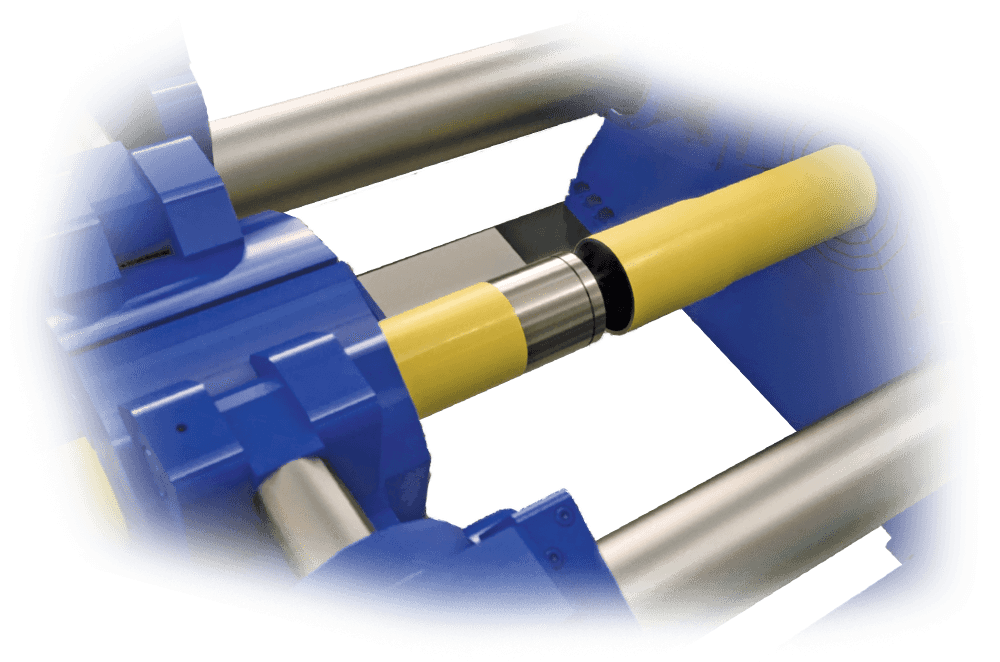

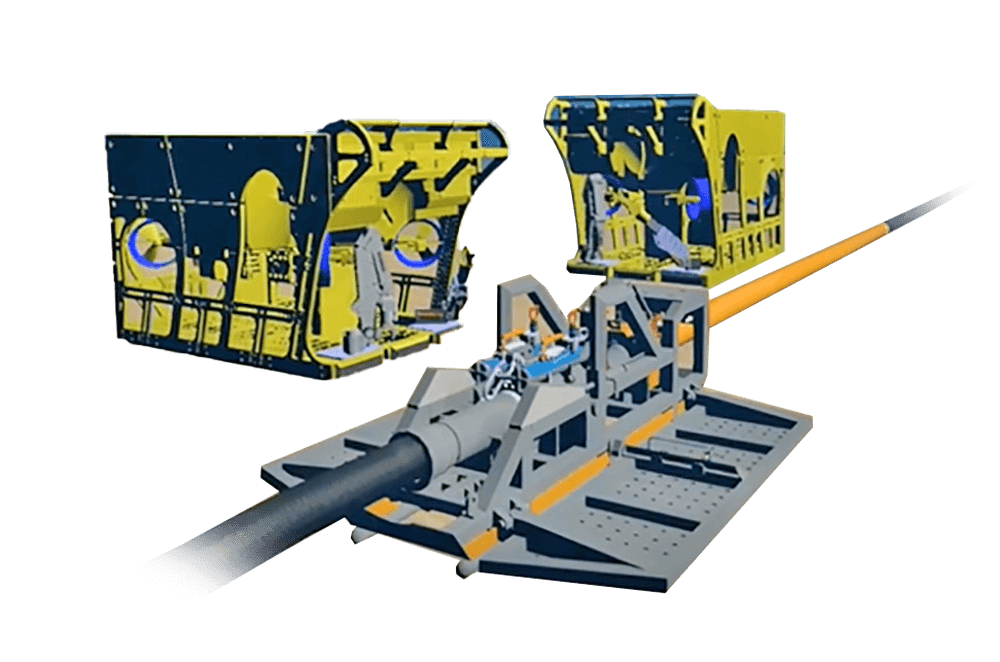

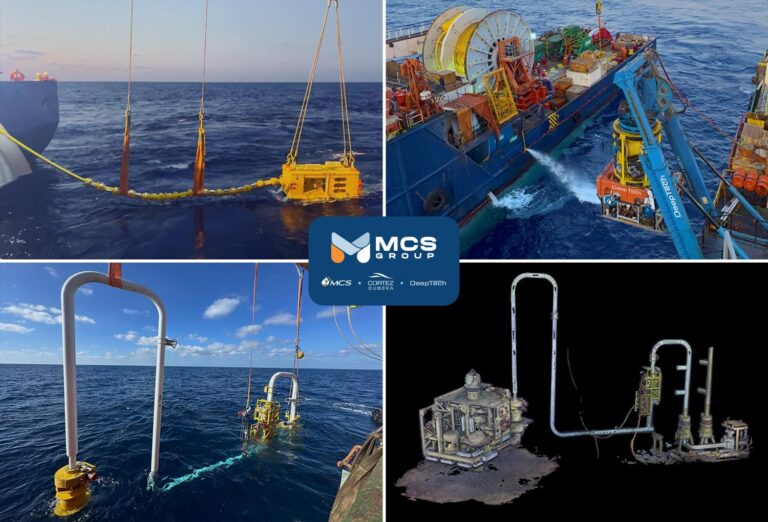

Cortez Subsea pioneers new ways to make subsea pipelay quicker, safer and cleaner for the global energy industry. We offer a fully integrated service from the spark of an idea through to the design and development of state-of-the-art technology, project planning and smart application in the field. We champion proven and alternative products to install pipeline in mature and shallow water regions around the world.

26Pipeline systems installed

5000+Mechanical interference fit connectors

10+Years of experience

Solutions

_

We lead the charge to offer the most cost-effective pipelay methods in the world

Innovation is in our DNA

_

Our innovations are discovered through continual investment in research and development.

With experts across underwater robotics, electronics, control, hydrodynamics, software, and mechanical design, we create and deliver unique products and services which enhance your projects while giving us a competitive advantage and opportunity to grow.

Group News and Insights

_